We have been working at Loess Hills Harley Davidson for the last year or so. Great people there. Especially Bill Fisher. We have painted the exterior and the interior of their store. Recently they asked us to fix caulking that a construction crew had done. It was really bad. The construction company installed new doors and then caulked the sides. It was horrible. The doors were installed as part of a remodel project of the store. We were there painting the new drywall. This job would require caulking with urethane caulk.

The proper caulk to use for this application is a urethane caulk. We used BASF NP1. This is something we have used before so we knew what we were getting into. Great caulk but it is not user friendly.

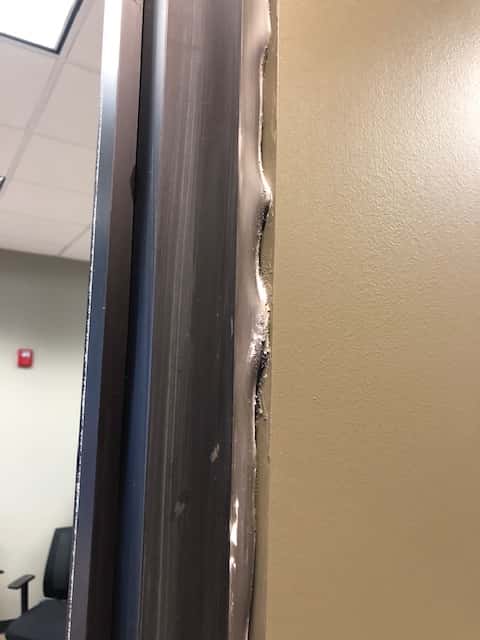

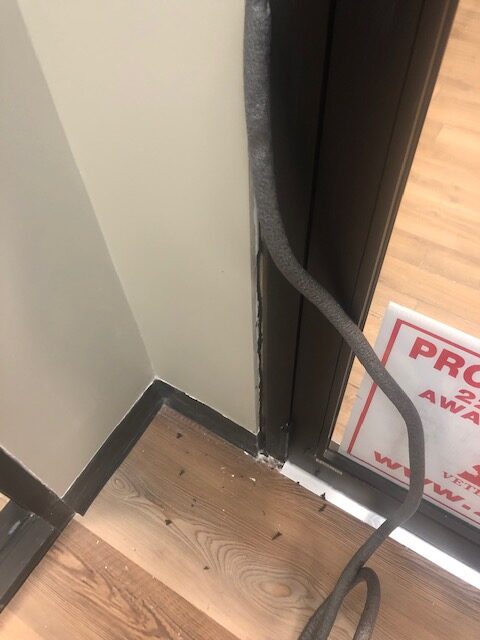

The biggest challenge was getting the old caulk removed. The only way to do this was by cutting it out. Not an easy task. When this type of caulking is done a “backer” rod is pushed into the opening which gives you something to caulk against. This step was skipped by whoever did this previously. There was so much caulk put into the gaps that much of it was uncured after about an inch deep. Most of the areas had over 2″ of caulk in the openings. It was not fun removing the wet caulking and trying to not make a mess. This stuff is not a soap and water cleanup either. When cleaning your hands, etc. you have to use a solvent. Because of this we had to be extra careful about what we touched or got caulk on. The solvent would damage painted surfaces.

We did manage to get the job finished. Not something I would want to do again soon.