Epoxy floors are labor intensive but they sure look beautiful when done. To do the job correctly, you must grind the floor. Some people don’t. Big mistake.

We use a hand grinder in hard to get to places like this job. There was no way we could get an upright grinder down the staircase so on our knees we went.

A vacuum system is essential when grinding concrete. So are ear plugs. It’s a very loud process. If you don’t use a good HEPA vacuum system you will very quickly fill the room to the point of not being able to see. Breathing that is very bad too.

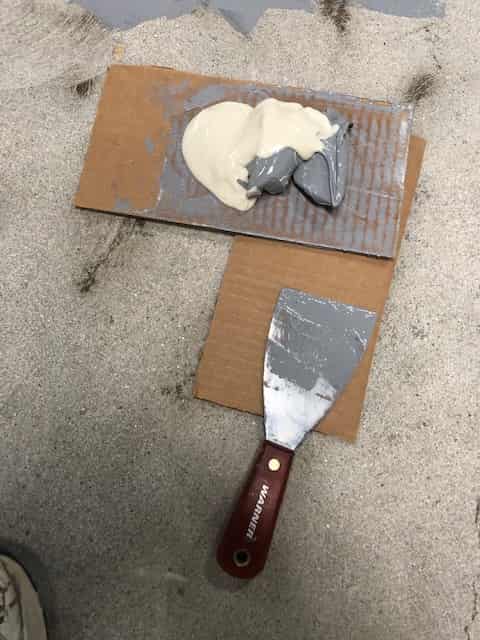

After the grinding is complete we use a special concrete patch material to fill cracks and holes. There are very few patch materials that can do the job and be top coated. The 2 component material we use can be top coated in 8 hours but we wait 24.

The patch material must be sanded after it’s cured. After which we vacuum again.

The primer coat is next. We double prime our epoxy floor jobs. On this job we are using MegaSeal primer and self leveling top coat. Once you get to this stage it is very important to observe the re-coat windows. How long you wait before applying the next coat and the maximum amount of time you can wait to recoat. Not paying attention to this is disastrous.

The self leveling product we used for the top coat is MegaSeal. Not an easy product to use. The pot life, or how long you have before it sets up, is about half of what they advertise so you have to work quickly. It is mixed up, poured out and spread on the floor. It gets cross rolled in two directions and then before it sets up we use a spike roller on it to release any air bubbles. All of this is done while wearing spike shoes. I haven’t fallen yet but I have had many close calls. This process is done again after the first coat cures over 24 hours.

A finished epoxy floor.